Hot work

[edit] Introduction

The term ‘hot work’ refers to processes that require the use of open flames or that produce sparks through heat and friction that could ignite into a fire. Hot works include:

- Riveting.

- Welding.

- Flame cutting.

- Brazing.

- Soldering.

- Thawing.

- Grinding and drilling (when flammable materials are present).

- Use of any equipment that incorporates a flame.

Hot works can pose a significant fire risk, from both the initial risks of ignition and as a cause of rapid fire spread. According to BS 9999, only if no satisfactory alternative method is feasible should hot work be undertaken.

Precautions should include:

- Carrying out the hot work outdoors or in specially-designated areas that minimise fire risk if possible.

- Scheduling hot works during periods when other works are quieter.

- Applying safe systems for undertaking the hot works.

In 2020, it was reported that research indicated hot works were to blame for 79% of all fires on construction sites in Scotland during the previous year. Ref http://www.constructionmanagermagazine.com/news/construction-firms-warned-hot-works-fire-risk/

[edit] Hot work permit

BS 9999 recommends that a ‘hot work permit’ be followed in order to ensure actions are taken to mitigate and minimise risks before, during and after the works. The permit is appropriate when there are flammable materials in close proximity to the works, and when the work environment is not ordinarily used for such activities.

The permit is used:

- To ensure there is a formal check confirming appropriate work processes are being adhered to.

- To provide time limits for safe working.

- To provide for special PPE (personal protective equipment) or communication methods.

- For coordinating work activities.

- To ensure proper supervision throughout.

When being employed to complete hot works contractors may be required to use the client’s hot work procedure, or they may use a suitable procedure of their own. In the case of the latter, the client must ensure that the contractor is using a suitable hot work procedure.

There are varying levels of risk depending on the type of work and the area within the building that it is taking place. As a result, the hot work permit system should be adapted to the particular needs and risks. In terms of the proposed works, the permit should be designed to provide as much information as possible.

Typically, the hot work permit will identify:

- Administrative details (permit title, number, job location, etc.).

- Description of the work to be undertaken.

- The person/s carrying out the work.

- Likely length of time to complete the work.

- Identified hazards and required precautions.

- Work methods that are required.

- Types of fire-fighting equipment available.

In addition, the permit will identify the requirements that must be met within the work area which include the following:

- Combustible materials removed before work commences.

- Floors swept clean and combustible surfaces covered with heat protections mats.

- Walls covered and combustibles moved away.

- Elimination of explosive atmosphere in the area.

- Removal of flammable liquids and gas cylinders.

- Appropriate screening, protection and display of safety notices.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

The Building Safety Forum at the Installershow 2025

With speakers confirmed for 24 June as part of Building Safety Week.

The UK’s largest air pollution campaign.

Future Homes Standard, now includes solar, but what else?

Will the new standard, due to in the Autumn, go far enough in terms of performance ?

BSRIA Briefing: Cleaner Air, Better tomorrow

A look back at issues relating to inside and outside air quality, discussed during the BSRIA briefing in 2023.

Restoring Abbotsford's hothouse

Bringing the writer Walter Scott's garden to life.

Reflections on the spending review with CIAT.

Retired firefighter cycles world to raise Grenfell funds

Leaving on 14 June 2025 Stephen will raise money for youth and schools through the Grenfell Foundation.

Key points for construction at a glance with industry reactions.

Functionality, visibility and sustainability

The simpler approach to specification.

Architects, architecture, buildings, and inspiration in film

The close ties between makers and the movies, with our long list of suggested viewing.

SELECT three-point plan for action issued to MSPs

Call for Scottish regulation, green skills and recognition of electrotechnical industry as part of a manifesto for Scottish Parliamentary elections.

UCEM becomes the University of the Built Environment

Major milestone in its 106-year history, follows recent merger with London School of Architecture (LSE).

Professional practical experience for Architects in training

The long process to transform the nature of education and professional practical experience in the Architecture profession following recent reports.

A people-first approach to retrofit

Moving away from the destructive paradigm of fabric-first.

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

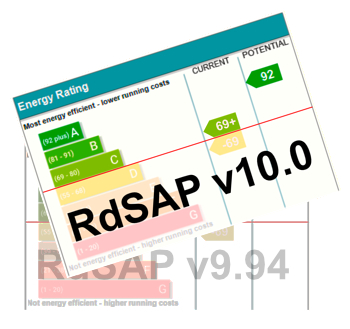

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.